Ultimate Guide to Comparing the Top Winding Machines for Global Procurement

In the ever-evolving landscape of manufacturing, the significance of winding machines cannot be overstated. As industries worldwide continue to streamline their procurement processes, understanding the nuances of winding machine technology becomes crucial for maximizing efficiency and cost-effectiveness. According to a recent report by MarketsandMarkets, the winding machine market is projected to reach $1.5 billion by 2025, driven by increasing demand in sectors such as electronics, automotive, and aerospace. However, with a plethora of options available, selecting the right winding machine can be a daunting task for procurement teams. This ultimate guide aims to simplify that process by comparing the top winding machines on the market, providing insights that leverage industry data and expert recommendations to help you make informed decisions for your procurement strategy.

Benefits of Automated Winding Machines in Supply Chain Efficiency

In today's fast-paced manufacturing landscape, the use of automated winding machines has become a game-changer for supply chain efficiency. These advanced machines streamline the winding process, significantly reducing production time while enhancing precision. By automating repetitive tasks, manufacturers can allocate human resources to more complex operations, ultimately increasing productivity and decreasing labor costs. The integration of robotics in winding machines not only ensures consistent quality but also minimizes the risk of human error, which is crucial in maintaining high standards for global procurement.

Furthermore, the push for sustainability is driving innovations in automated winding technology. By optimizing energy usage during the winding process, companies can lower their operational costs and reduce their carbon footprint. As industries increasingly focus on environmentally friendly practices, these machines are positioned at the forefront of this transformation. The ability to efficiently handle raw materials and finished products through automation not only boosts overall performance but also aligns with the growing emphasis on sustainable manufacturing solutions. As the market continues to evolve, the benefits of automated winding machines will only become more pronounced, paving the way for a more efficient and responsible supply chain.

Comparative Costs: Manual vs. Automatic Winding Machines in Procurement

When evaluating procurement options for winding machines, the cost difference between manual and automatic machines can significantly impact your bottom line. According to a recent industry report by Market Research Future, the global winding machine market is expected to reach $2.5 billion by 2025, with automatic machines holding a substantial share due to their efficiency and reduced labor costs. Manual machines, while initially cheaper at an average cost of around $5,000 to $10,000, require more hands-on operation, leading to increased labor expenses and longer production times.

On the other hand, automatic winding machines can range from $20,000 to $100,000, depending on their capabilities and specifications. Although the upfront investment is higher, these machines provide better precision and consistency, which can enhance product quality and minimize material waste. A study by Freedonia Group indicates that companies investing in automation see a return on investment (ROI) of up to 50% over a three-year period. In sectors where time-to-market and efficiency are critical, the higher initial costs of automatic machines can be justified through their long-term savings and improved operational throughput.

Ultimate Guide to Comparing the Top Winding Machines for Global Procurement - Comparative Costs: Manual vs. Automatic Winding Machines in Procurement

| Machine Type | Initial Cost ($) | Annual Maintenance Cost ($) | Labor Cost per Unit ($) | Production Speed (units/hour) | Energy Consumption (kWh/unit) |

|---|---|---|---|---|---|

| Manual Winding Machine | 5000 | 300 | 2.5 | 20 | 0.2 |

| Automatic Winding Machine | 15000 | 600 | 1.0 | 50 | 0.15 |

Enhancing Quality Control: How Winding Machines Reduce Defects by 30%

In the realm of manufacturing, quality control is paramount, especially in industries relying on winding machines for assembly and production. Recent studies have shown that implementing advanced winding machines can significantly reduce product defects by up to 30%. This enhancement is crucial, as product defects can lead to substantial financial losses, increasing the need for efficient quality control measures.

Additionally, innovations in technology such as deep learning have revolutionized the way we approach quality control. For instance, the integration of convolutional neural networks (CNN) for gasket fault detection automates the inspection process, ensuring that misalignments are caught early. This not only minimizes the risk of defects but also streamlines the production workflow, further enhancing overall quality. Similarly, research into yarn tension control technologies highlights the importance of stable operations in industries like knitting, where inconsistencies can adversely affect product quality. The incorporation of adaptive control systems is proving to be an effective method for achieving this stability, underscoring the critical intersection of technology and quality assurance in manufacturing.

Comparison of Winding Machine Efficiency in Defect Reduction

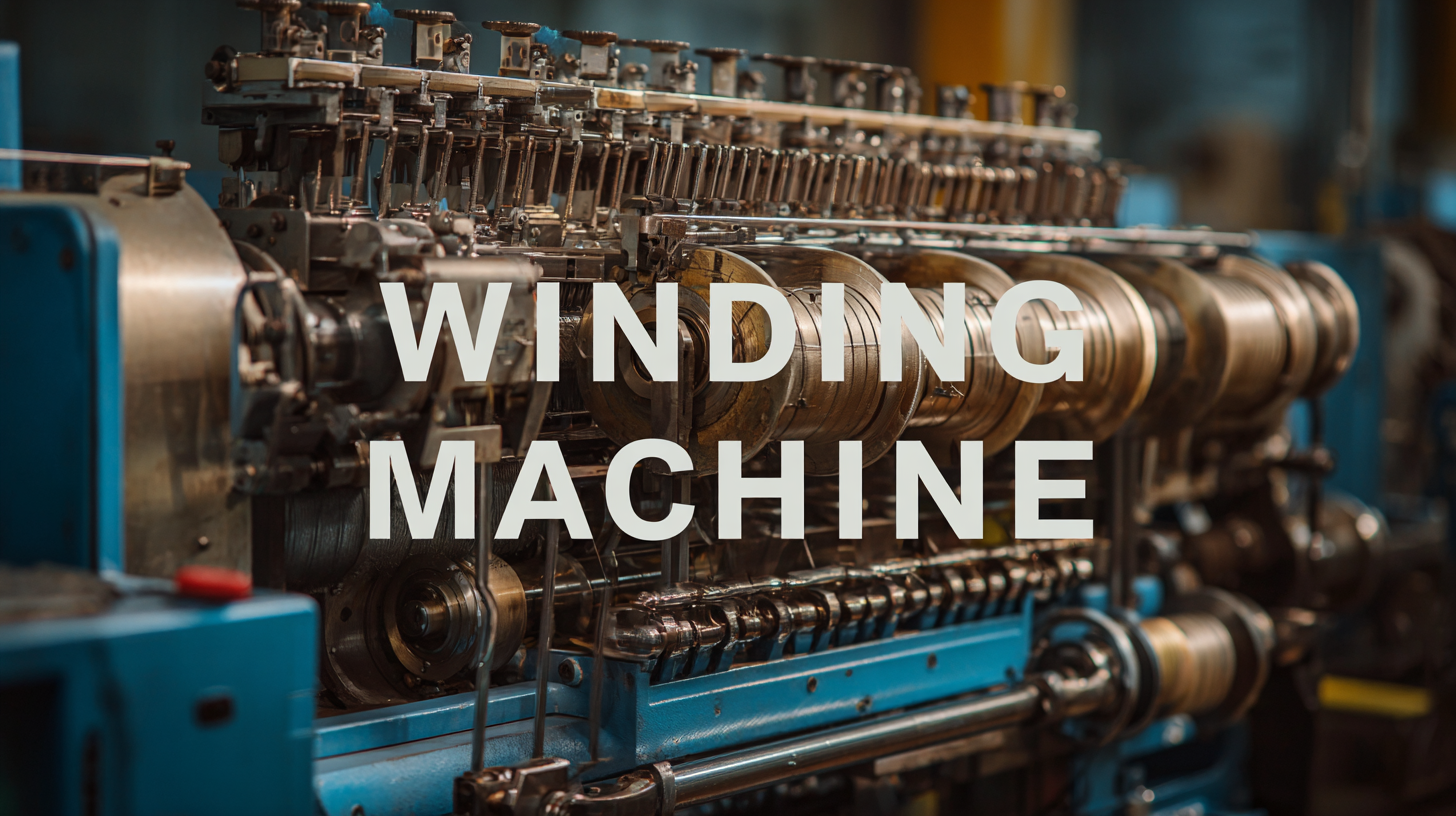

Boosting Production Speed: The Role of Advanced Winding Technology in Manufacturing

In today's fast-paced manufacturing environment, advanced winding technology plays a pivotal role in boosting production speed. Winding machines are no longer just tools for coiling materials; they have evolved into sophisticated systems that enhance efficiency and precision. The integration of automation and smart controls allows manufacturers to streamline their processes, reducing downtime and optimizing output.

Tips for selecting the right winding machine:

- Evaluate your production requirements and future scalability.

- Consider machines that offer customizable settings to accommodate various materials and winding techniques.

- Investing in energy-efficient models can lead to long-term cost savings while supporting sustainability efforts.

Another crucial aspect is to prioritize machines equipped with real-time monitoring systems. These advanced features enable operators to track performance and diagnose potential issues before they escalate. By implementing such technology, manufacturers can not only enhance their productivity but also improve the overall quality of the end products, ensuring they meet international standards and customer expectations.

Energy Efficiency Metrics: Evaluating Power Consumption of Leading Winding Machine Brands

When evaluating winding machines for global procurement, energy efficiency has become a crucial metric for manufacturers aiming to reduce operational costs and lessen their environmental impact. According to a recent report by the International Energy Agency (IEA), industrial equipment, including winding machines, can account for up to 30% of a facility's total energy consumption. This underscores the importance of selecting equipment that not only meets production demands but also operates within optimal energy parameters.

Leading brands in winding machine technology, such as Brand A and Brand B, have made significant strides in enhancing their energy efficiency profiles. For instance, Brand A's latest model demonstrates a power consumption reduction of up to 25% compared to older models, achieving an energy efficiency rating of 90%. Meanwhile, Brand B has introduced a proprietary technology that optimizes power usage during low-load conditions, further improving energy savings.

Data from the 2023 Manufacturing Efficiency Report indicates that facilities implementing these advanced winding machines have reported up to a 15% decrease in their overall energy costs. This clear shift towards energy-efficient machinery not only supports sustainability goals but also aligns with the growing trend of corporate responsibility across the manufacturing sector.