The Ultimate Guide to Finding Top Quality Winding Machine Suppliers for Global Buyers

In today's fast-paced manufacturing environment, the demand for high-quality winding machines is on the rise, driven by the increasing need for precision and efficiency across various industries. According to a recent report from MarketsandMarkets, the global winding machine market is projected to reach USD 2.1 billion by 2026, growing at a CAGR of 4.5% from 2021 to 2026. This growth is primarily fueled by advancements in technology and the proliferation of electric vehicles, which require sophisticated winding processes for their motors and batteries.

As a global buyer, navigating the plethora of suppliers can be daunting, but understanding key factors such as quality standards, technological innovations, and supplier reliability is crucial. This guide aims to equip you with essential tips to identify top-quality winding machine suppliers that not only meet your manufacturing requirements but also help you stay competitive in a rapidly evolving market.

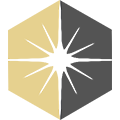

Understanding the Importance of High-Quality Winding Machines in Global Markets

In today’s global market, the significance of high-quality winding machines cannot be overstated. These machines play a crucial role in various industries, from electronics to textiles, where precision and durability are paramount. A reliable winding machine ensures that products are manufactured efficiently, reducing waste and increasing overall productivity. When businesses prioritize quality, they not only improve their operational capacities but also enhance their competitive edge in the market.

**Tip 1:** When sourcing winding machines, always consider the supplier's reputation. Look for reviews and testimonials from previous clients to assess their reliability and product quality.

The procurement of winding machines should also align with the specific needs of your business. Each application may require different features or capabilities, making it essential to identify the specifications that will support your production processes effectively.

**Tip 2:** Engage directly with potential suppliers to discuss your unique requirements. This dialogue can provide valuable insights into how their machines perform in real-world applications.

Choosing top-quality winding machine suppliers can significantly impact your production efficiency and product output, making the selection process one of the most important decisions for global buyers today.

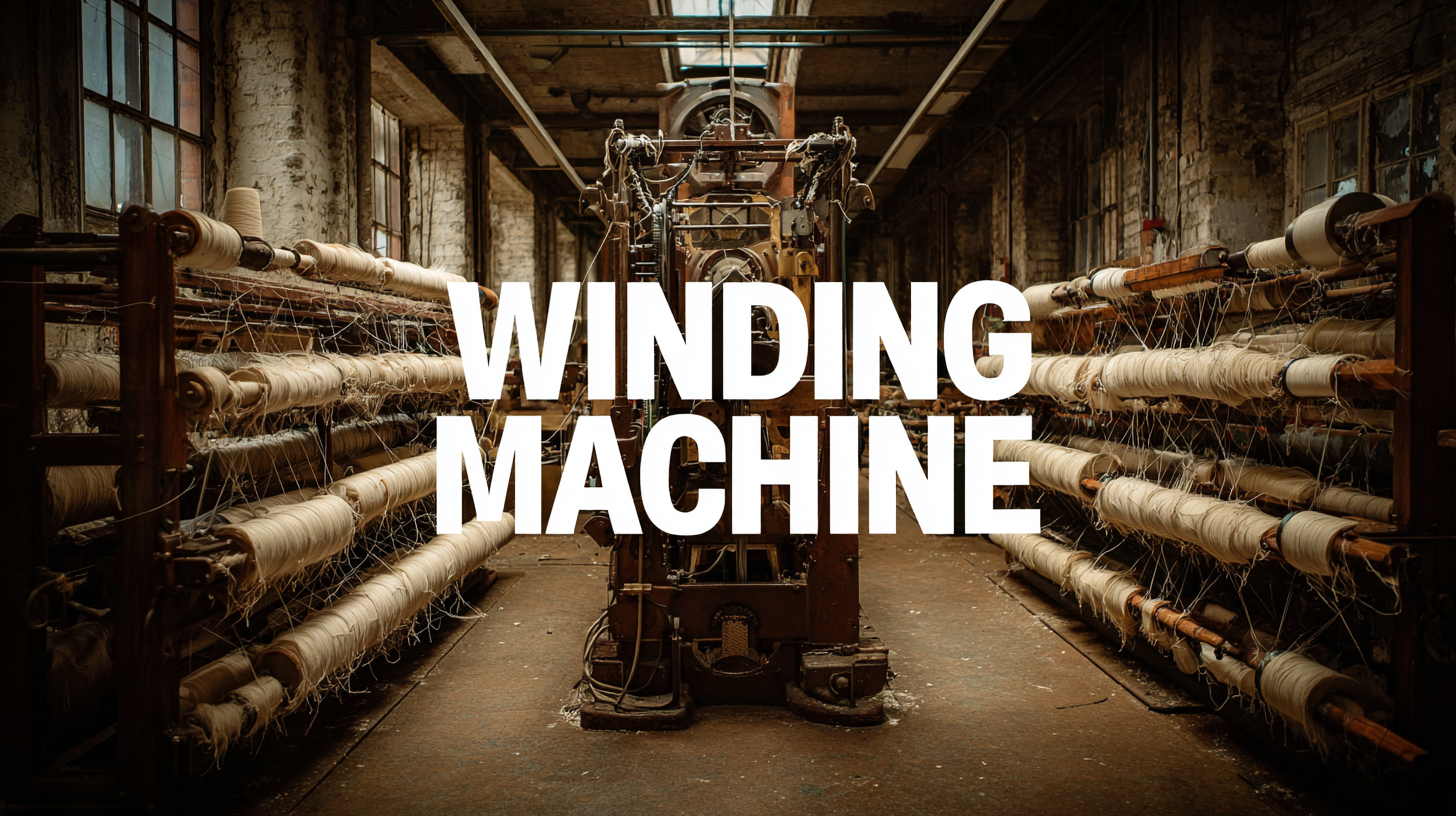

Criteria for Evaluating Top Winding Machine Suppliers: What to Look For

When searching for top winding machine suppliers, it is essential to evaluate several key criteria to ensure you find a partner that meets your quality and service expectations. First and foremost, assess the supplier's industry reputation. Look for companies with a proven track record of delivering reliable and efficient winding machines, as well as positive reviews from existing clients. A supplier with a strong market presence often indicates stability and expertise, which can be crucial for your long-term manufacturing needs.

In addition to reputation, consider the supplier's technical capabilities. This includes their ability to customize winding machines to fit specific production requirements and their access to the latest technology and innovation in winding equipment. It's also important to inquire about their quality control processes and certifications, as these factors will ensure that the machines you receive meet global standards. By focusing on these criteria, global buyers can more effectively identify the right winding machine suppliers to partner with for their manufacturing needs.

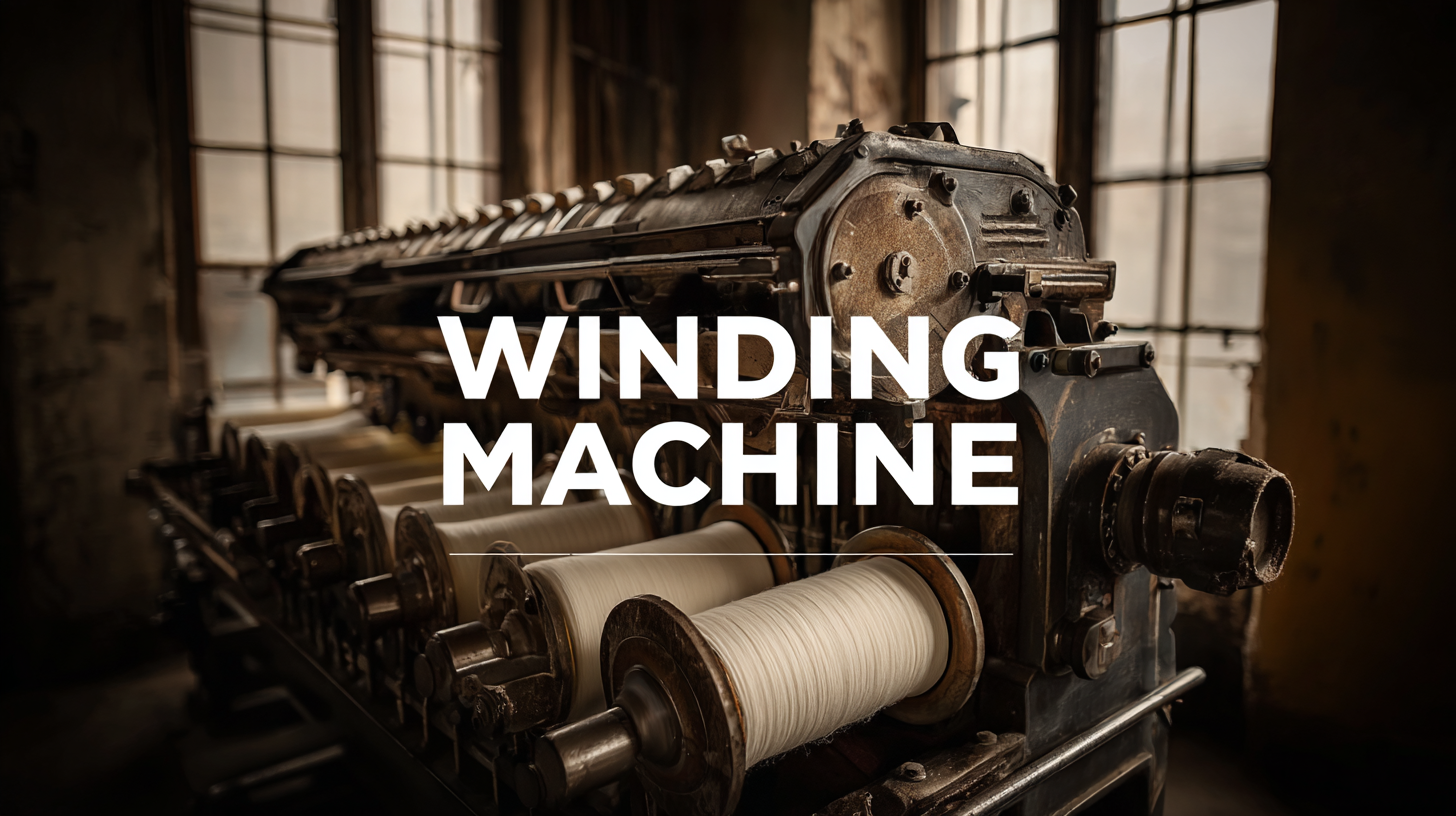

Key Benefits of Partnering with Chinese Manufacturers for Winding Machines

Partnering with Chinese manufacturers for winding machines offers numerous advantages that can significantly enhance production efficiency and cost-effectiveness. According to a report by ResearchAndMarkets, the global winding machines market is projected to reach approximately $5 billion by 2026, with Asia-Pacific driving much of this growth, primarily due to the robust manufacturing capabilities in China. Chinese manufacturers have advanced technologies and extensive experience, enabling them to produce high-quality winding machines that meet international standards.

Moreover, collaborating with Chinese suppliers can lead to substantial cost savings. A study from McKinsey & Company indicates that manufacturers can save up to 20-30% on production costs by sourcing from China. These savings are often a result of lower labor costs, a well-established supply chain, and economies of scale that Chinese manufacturers can leverage. Additionally, many Chinese companies now prioritize sustainability and innovation, incorporating eco-friendly practices and smart technology into their winding machine production processes, which aligns with global trends towards greener manufacturing. Such advancements not only improve operational efficiency but also position businesses to meet the growing demand for sustainable practices in manufacturing.

The Benefits of Partnering with Chinese Manufacturers for Winding Machines

Navigating the Supplier Landscape: How to Identify Reliable Winding Machine Partners

In the winding machine industry, identifying reliable suppliers is crucial for global buyers looking to enhance their production capabilities. According to a report by MarketsandMarkets, the winding machine market is expected to grow from $5.1 billion in 2023 to $7.2 billion by 2028, with a compound annual growth rate (CAGR) of 7.4%. This growth underscores the importance of partnering with high-quality suppliers who can adapt to evolving technologies and meet increasing demands.

To navigate the supplier landscape effectively, buyers should consider several key factors. First, evaluate the supplier's technical expertise and product offerings. A supplier with a diverse range of machinery, including CNC winding machines and automated solutions, can provide more tailored options for specific production needs. Additionally, assessing a supplier's reputation within the industry and their commitment to customer feedback is vital. Reports indicate that suppliers with strong customer service ratings correlate with enhanced product performance and buyer satisfaction. By focusing on these criteria, global buyers can forge robust partnerships that elevate their manufacturing processes.

Building Long-Term Relationships with Winding Machine Suppliers: Best Practices

Building long-term relationships with winding machine suppliers is crucial for global buyers seeking consistency and quality in manufacturing processes. Engaging with suppliers beyond mere transactional interactions helps create a foundation of trust, ensuring that both parties understand each other's needs and expectations. Regular communication is key; setting up periodic meetings or check-ins can significantly enhance collaboration and foster transparency in operations.

Another best practice is to invest time in understanding your suppliers' capabilities and challenges. This could involve on-site visits, where buyers can observe the manufacturing processes and quality control measures in place. By demonstrating genuine interest in their operations, buyers not only gain valuable insights but also position themselves as partners rather than just customers. Furthermore, offering feedback on performance can help suppliers refine their processes, ultimately benefiting both sides and leading to improved product quality and service reliability.

| Supplier Location | Machine Type | Quality Certifications | Years in Business | Average Lead Time (Days) | Customer Support Availability |

|---|---|---|---|---|---|

| Germany | Automatic Winding Machine | ISO 9001, CE | 20 | 30 | 24/7 |

| USA | Semi-Automatic Winding Machine | ISO 13485 | 15 | 45 | Business hours |

| China | Fully Automatic Winding Machine | ISO 9001 | 10 | 60 | Weekdays only |

| Japan | High-Speed Winding Machine | JIS, CE | 25 | 35 | 24/7 |